Featuring cutting-edge detector technology on the basis of semiconductor detectors that were specially developed for emission spectroscopy, OBLF’s VeOS spark emission spectrometer enables versatile, flexible and quick analysis of all common metallic materials. The analytical spectrum also includes the precise analysis of short wavelength elements like nitrogen or low carbon.

Featuring cutting-edge detector technology on the basis of semiconductor detectors that were specially developed for emission spectroscopy, OBLF’s VeOS spark emission spectrometer enables versatile, flexible and quick analysis of all common metallic materials. The analytical spectrum also includes the precise analysis of short wavelength elements like nitrogen or low carbon.

- Complete and flexible inclusion of all analytical tasks

- Easily extendable features

- The latest, specially developed detector technology

- Excellent performance with regard to detection limit, precision, stability

- Robust design for use in heavy-duty environments

- Most comprehensive multi-matrix application options without any restrictions

regarding the selection of elements for analysis - Accurate detection of N and traces of carbon (ULC)

OBLF’s VeOS is the first spark spectrometer to feature a semiconductor-based detector system whose analytical performance – including the spectral resolution required for a laboratory spectrometer – is every bit as good as established photomultiplier-based systems. This brand new photo-detector technology was specifically developed for spark emission spectroscopy and guarantees excellent results over the entire required wavelength range of 130 to 800 nm. The design of the light-sensitive detectors, which are characterised by a surface that is 100 times more light sensitive than detectors found in conventional systems, was specially adapted to suit the requirements of emission spectroscopy. As a result, this is the first device to offer the best possible combination of spectral sensitivity and spectral resolution along with an innovative design that both guarantees OBLF’s well-known quality and the greatest flexibility of use.

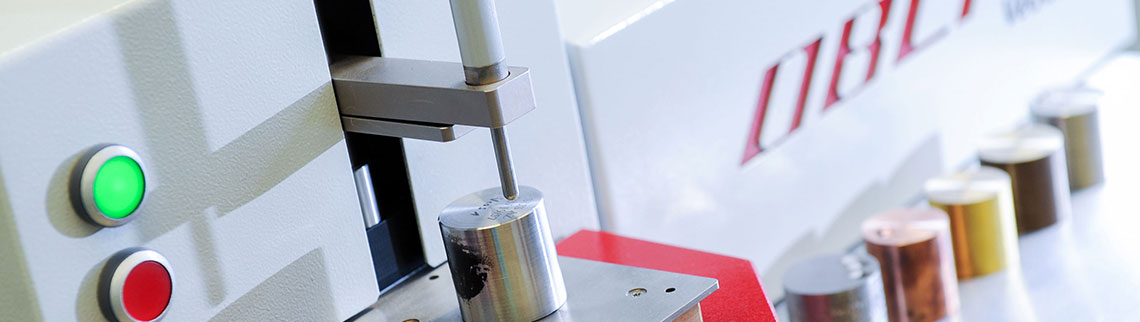

In addition to this, the VeOS model comes in a new, operator-friendly housing. Being both simple to operate and of compact, solid design, the spectrometer is highly suitable for use in production environments but also for goods receipt and materials control purposes as well as in test labs with diverse analytical tasks. Subsequent extensions of the analytical capabilities are easily possible without having to make major system changes.

In order to guarantee that external conditions at the place of installation cannot influence the system, the detectors and the specially developed readout system have been housed in the temperature-stabilised vacuum optical system. As in all OBLF spectrometers, the VeOS makes use of maintenance-free, digital GDS III excitation, which, in conjunction with short analysis times, enables optimised spark discharges to be generated for any given application. Thanks to OBLF’s patented automatic pulse cleaning system, the optimised spark stand only requires very infrequent maintenance and can be operated at low cost. The new Windows®-based spectrometer software, OBLFWin, permits simple operation of the machine and offers all the usual settings needed for spark spectroscopy.

Optics

- spectrometer in Paschen-Runge mounting

- Rowland circle diameter 500 mm

- wavelength range 130-700 nm

- optics and read-out electronics temperature stabilised to ± 0.1°C for excellent long-term stability

- cooled optics and read-out system

- automatic computer controlled profiling

- optimised detector lines for each wavelength region

- high UV sensitivity without sensor coating

- shock resistance

Vacuum System

- evacuated light metal chamber

- maintenance free 2-stage rotary vane pump

- vacuum pump integrated in cabinet

- pump duty cycle <5%

- oil diffusion protection

- automatic pressure regulation and stabilisation

Spark Generator

- Gated Digital Source (GDS) with integrated multi-spark system

- maintenance free

- spark frequency up to 1 kHz

- unipolar medium voltage discharge

- separate parameter for pre-sparking and integration selectable

- variable excitation parameters & discharge characteristics selectable by software

- Ignition voltage 20kV

Spark Stand

- Argon purged spark stand, optimised for low Ar consumption

- patented self-cleaning

- open sample stand for easy handling

- low-wear top plate with 12 mm opening

- optionally adapters for small parts and wires are available

- low-wear tungsten electrode

- pneumatic sample clamp for rapid sample handling

- automatic electrode cleaning as option

- About 3 l Argon consumption per measurement

- easy maintenance

Electronics

- 16 Bit AD conversion for each pixel

- DSP processor controlled sensor read-out

- USB interface to spectrometer PC

Dimensions & Weight

- width 74 cm

- height 134 cm

- depth 115 cm

- weight about 300 kg

Power Supply

- 230V; 50/60 Hz; 1,5 kVA

- 300 W in stand-by mode

Environmental Conditions

- operation temperature 10 – 40 ºC

Computer-Hardware

- standard computer system

- MS Windows® 10 operating system with custom specific regional and language settings

Software

- OBLFwin spectrometer program

- easy routine operation

- freely configurable sample IDs

- automatic repeatability control for measurements

- automatic averaging

- warning signal if calibration is exceeded

- bad sample detection

- as many analysis programs to customer specifications as required

- individual analysis parameters for each program

- multivariate calibration model (incl. line overlaps and matrix effects)

- easy and simultaneous recalibration of a complete matrix

- automatic program selection

- type calibration and type measurement

- spectrometer control sample measurements

- average and standard deviation from chosen measurements

- automatic reminder of regular recalibration

- grade control by comparison with grade database settings

- automatic display of of selected grade or material number

- freely editable grade database

- printout of certificates

- analysis database

- several statistical functions as display of control charts

- automatic analysis data export

- system check preceding each analyse

- system diagnostics module

- software supported maintenance tasks, for example entrance window cleaning

- single spark evaluation module as option

- Module for the display of emission spectra and line definition