Conventional Systems

Sample analysis using spark emission spectrometry usually requires at least two sparkings at various positions on the sample surface to ensure any inhomogeneities such as inclusions and blow holes are detected and a realistic average can be calculated. Since the sample has to be moved between the measurings, the total analysis time is therefore made up not only of the time taken for the sparkings but also the time for positioning and re-positioning of the sample.

Across the years, the demand of further shortening of the analysis time has arisen – especially by primary producers as foundries and steelworks. In the beginning, we were able to fulfill this with higher pre-sparking energies and spark frequencies, but the physical limits are now hit. Therefore, OBLF has introduced a completely new technique which is as stunning easy as effective.

Double Electrode Spark Stand

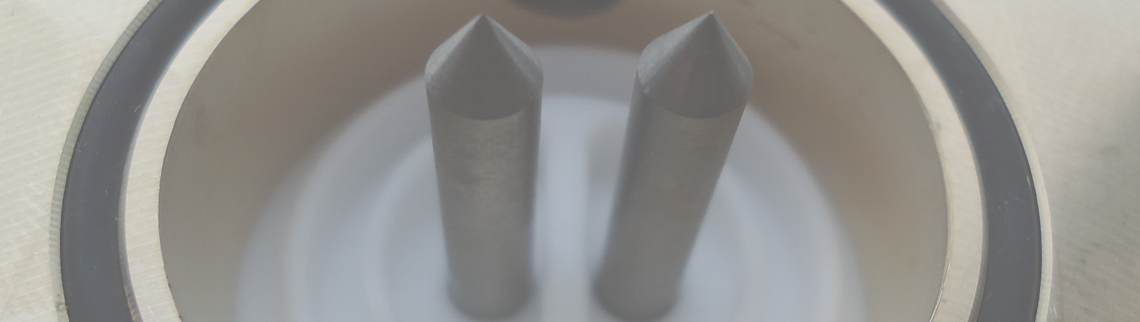

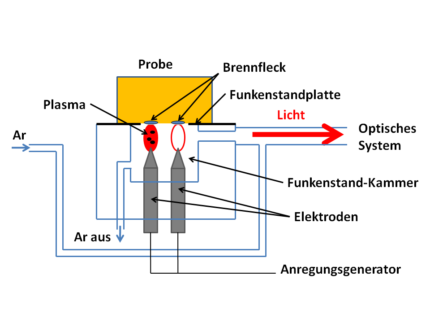

On an analysis, the sample is positioned on the hole of the spark stand, which is argon-flushed before sparking in order to cast out air. By high-voltage application an electric spark is created between the electrode and the sample. The created erosion of sample material is atomized and thermally stimulated in the plasma. On the sample a burn spot is marked. For the next measuring the sample must be moved. So far so good! But why not shape the spark stand hole oval instead of circular in order to include two instead of one electrodes? Hereby it would be possible to perform measurings on two different positions without moving the sample. No sooner said than done. We call the new spark stand double electrode spark stand. Exemplarily to be seen in below drawing:

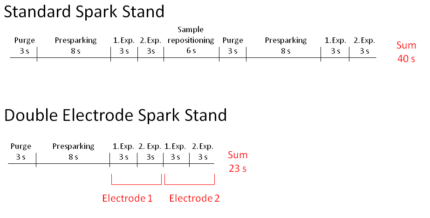

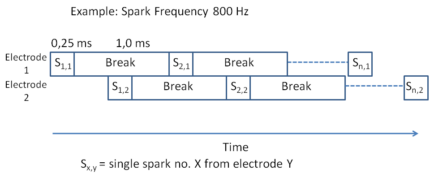

The time saving is not only limited to the re-positioning of the sample, but also the purge is only made once, as both electrodes are in the same spark stand. Additionally, by introduction of a new, high-performance excitation generator with higher frequency, it is possible to prespark both burn spots alternating without their plasmas influencing each other. The following exposure times (Exp.) are simply executed in rotation. The following time schemes show the time saving by comparing the standard and the double electrode spark stand on example of a steel sample.

Whereas a complete analysis including nitrogen takes about 40 seconds on a standard spark stand, it only needs 23 seconds when using a double electrode spark stand. The calculated concentration of both burn spots are displayed on the screen as separate sparkings, which are automatically averaged when inside the tolerances. This means: press start once, wait 23 seconds, analysis done. It´s as simple as that! The double electrode spark stand is available for our spectrometer models QSG 750-II, QSN 750-II and GS 1000-II.

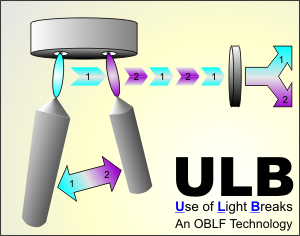

ULB

OBLF has included a special treat on QSG 750-II instruments using double electrode spark stand: in addition to the presparking, the exposure times are alternating, too. As all light impulses are captured by the integration system, each individual spark signal is separately integrated and the values are saved specific to the electrodes. We use the break on electrode 1 to create a spark on electrode 2. The utilization of these breaks leads to the name of the technique: ULB = Use of Light Breaks, exemplarily to be seen in following drawing:

The analysis time is hereby further reduced to a total of less than 20 s.

In the meanwhile, this technique was successfully installed in iron and aluminium foundries as well as in steelworks.

read more »